SLIP ON FLANGES

is a dynamic group, which was established over a decade ago to cater to growing demands of Slip On Flanges standards in ASME / ANSI B16.5 Flanges,ASME/ANSI B16.47 etc in all materials like Stainless Steel , Carbon Steel & High Nickel Alloys.

Slip On Flange is slightly larger than the outer diameter of the pipe it is to be used with. The pipe is slipped into the Flange prior to welding both inside and outside. High quality Slip on Flanges are ideal for lower pressure applications.

We Manufacture, Export and Supply Flanges which meets with national and international quality standards and producing base which owns equipments conforming to international technical level and is well equipped with a whole set of advanced plasma refining equipments.

We export our high quality Slip On flanges to Kuwait, Egypt and Qatar.

SPECIFICATIONS OF SLIP ON FLANGES

Range: ½” (15 NB) to 48” (1200NB)

Pressure Ratings: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. available with NACE MR 01-75

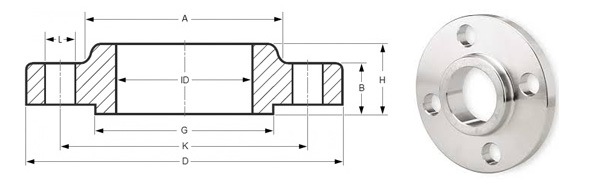

DIMENSIONS OF WELD NECK FLANGES

ANSI/ASME/ASA B16.5 150lb/sq.in. Flange SO-RF |

ø |

D |

b |

g |

m |

J |

h |

k |

Holes |

l |

Kg. |

1/2" |

88,9 |

11,1 |

34,9 |

30,2 |

22,3 |

15,9 |

60,3 |

4 |

15,9 |

0,400 |

3/4" |

98,4 |

12,7 |

42,9 |

38,1 |

27,7 |

15,9 |

69,8 |

4 |

15,9 |

0,700 |

1" |

107,9 |

14,3 |

50,8 |

49,2 |

34,5 |

17,5 |

79,4 |

4 |

15,9 |

0,800 |

1 1/4" |

117,5 |

15,9 |

63,5 |

58,8 |

43,2 |

20,6 |

88,9 |

4 |

15,9 |

1,100 |

1 1/2" |

127,0 |

17,5 |

73,0 |

65,1 |

49,5 |

22,2 |

98,4 |

4 |

15,9 |

1,400 |

2" |

152,4 |

19,0 |

92,1 |

77,8 |

62,0 |

25,4 |

120,6 |

4 |

19,0 |

2,200 |

2 1/2" |

177,8 |

22,2 |

104,8 |

90,5 |

74,7 |

28,6 |

139,7 |

4 |

19,0 |

3,600 |

3" |

190,5 |

23,8 |

127,0 |

107,9 |

90,7 |

30,2 |

152,4 |

4 |

19,0 |

4,100 |

3 1/2" |

215,9 |

23,8 |

139,7 |

122,2 |

103,4 |

31,7 |

177,8 |

8 |

19,0 |

5,200 |

4" |

228,6 |

23,8 |

157,2 |

134,9 |

116,1 |

33,3 |

190,5 |

8 |

19,0 |

5,600 |

5" |

254,0 |

23,8 |

185,7 |

163,6 |

143,8 |

36,5 |

215,9 |

8 |

22,2 |

6,300 |

6" |

279,4 |

25,4 |

215,9 |

192,1 |

170,7 |

39,7 |

241,3 |

8 |

22,2 |

7,500 |

8" |

342,9 |

28,6 |

269,9 |

246,1 |

221,5 |

44,4 |

298,4 |

8 |

22,2 |

12,600 |

10" |

406,4 |

30,2 |

323,8 |

304,8 |

276,3 |

49,2 |

361,9 |

12 |

25,4 |

18,500 |

12" |

482,6 |

31,7 |

381,0 |

365,1 |

327,1 |

55,6 |

431,8 |

12 |

25,5 |

28,000 |

14" |

533,4 |

34,9 |

412,7 |

400,0 |

359,1 |

57,1 |

476,2 |

12 |

28,6 |

36,000 |

16" |

596,9 |

36,5 |

469,9 |

457,2 |

410,5 |

63,5 |

539,7 |

16 |

28,6 |

46,000 |

18" |

635,0 |

39,7 |

533,4 |

504,8 |

461,8 |

68,3 |

577,8 |

16 |

31,7 |

50,000 |

20" |

698,5 |

42,9 |

584,2 |

558,8 |

513,1 |

73,0 |

635,0 |

20 |

31,7 |

64,000 |

22" |

749,3 |

46,0 |

641,2 |

609,6 |

564,4 |

79,4 |

692,1 |

20 |

34,9 |

72,000 |

24" |

812,8 |

47,6 |

692,1 |

663,6 |

615,9 |

82,5 |

749,3 |

20 |

34,9 |

89,000 |

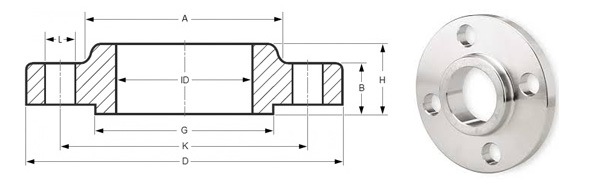

ANSI/ASME/ASA B16.5 600lb/sq.in. Flange WN-RF |

ø |

D |

b |

g |

m |

J |

h |

k |

Holes |

l |

Kg. |

1/2" |

95,2 |

14,3 |

34,9 |

38,1 |

22,3 |

22,2 |

66,7 |

4 |

15,9 |

0,800 |

3/4" |

117,5 |

15,9 |

42,9 |

47,6 |

27,7 |

25,4 |

82,5 |

4 |

19,0 |

1,400 |

1" |

123,8 |

17,5 |

50,8 |

54,0 |

34,5 |

27,0 |

88,9 |

4 |

19,0 |

1,600 |

1 1/4" |

133,3 |

20,6 |

63,5 |

63,5 |

43,2 |

28,6 |

98,4 |

4 |

19,0 |

2,100 |

1 1/2" |

155,6 |

22,2 |

73,0 |

69,8 |

49,5 |

31,7 |

114,3 |

4 |

22,2 |

3,100 |

2" |

165,1 |

25,4 |

92,1 |

84,1 |

62,0 |

36,5 |

127,0 |

8 |

19,0 |

3,700 |

2 1/2" |

190,5 |

28,6 |

104,8 |

100,0 |

74,7 |

41,3 |

149,2 |

8 |

22,2 |

5,400 |

3" |

209,5 |

31,7 |

127,0 |

117,5 |

90,7 |

46,0 |

168,3 |

8 |

22,2 |

7,300 |

3 1/2" |

228,6 |

34,9 |

139,7 |

133,3 |

103,4 |

49,2 |

184,1 |

8 |

25,4 |

8,900 |

4" |

273,0 |

38,1 |

157,2 |

152,4 |

116,1 |

54,0 |

215,9 |

8 |

25,4 |

11,800 |

5" |

330,2 |

44,4 |

185,7 |

188,9 |

143,8 |

60,3 |

266,7 |

8 |

28,6 |

24,500 |

6" |

355,6 |

47,6 |

215,9 |

222,2 |

170,7 |

66,7 |

292,1 |

12 |

28,6 |

29,500 |

8" |

419,1 |

55,6 |

269,9 |

273,0 |

221,5 |

76,2 |

349,2 |

12 |

31,7 |

43,000 |

10" |

508,0 |

63,5 |

323,8 |

342,8 |

276,3 |

85,7 |

431,8 |

16 |

34,9 |

70,000 |

12" |

558,8 |

66,7 |

381,0 |

400,0 |

327,1 |

92,1 |

488,9 |

20 |

34,9 |

86,000 |

14" |

603,2 |

69,8 |

412,7 |

431,8 |

359,1 |

93,7 |

527,0 |

20 |

38,1 |

100,000 |

16" |

685,8 |

76,2 |

469,9 |

495,3 |

410,5 |

106,4 |

603,2 |

20 |

41,3 |

142,000 |

18" |

742,9 |

82,5 |

533,4 |

546,1 |

461,8 |

117,5 |

654,0 |

20 |

44,4 |

175,000 |

20" |

812,8 |

88,9 |

584,2 |

609,6 |

513,1 |

127,0 |

723,9 |

24 |

44,4 |

232,000 |

22" |

869,9 |

95,2 |

641,2 |

666,7 |

564,4 |

133,3 |

777,9 |

24 |

47,6 |

292,000 |

24" |

939,8 |

101,6 |

692,1 |

717,5 |

615,9 |

139,7 |

838,2 |

24 |

50,8 |

330,000 |

DIN86029 PN10 Hubbed Slip-on Flange For Welding

DIN86029 PN10 Hubbed Slip-on Flange For Welding in forged steel, Stainless Steel, Carbon steel: C22.8, RST37.2, S235JR, P235GH, P245GH, P250GH, ASTM A105, ASTM A182 F304 (1.4306), F304L(1.4307), F316(1.4404), F316L(1.4404), F321(1.4541) etc.

Rated Diameter

| O.D. of Pipe

| Flange Parameter

| Neck Size

| Size of R.F.

| Bolts

| Approx. Weight

|

| DN

| d1

| D

| d5

| b

| k

| h

| d3

| r

| d4

| f

| No. of

holes

| d2

| KG

|

10 |

17.2 |

90 |

17.7 |

14 |

60 |

20 |

30 |

4 |

40 |

2 |

4 |

14 |

0.56 |

15 |

21.3 |

95 |

22 |

14 |

65 |

20 |

35 |

4 |

45 |

2 |

4 |

14 |

0.62 |

20 |

26.9 |

105 |

27.6 |

16 |

75 |

24 |

45 |

4 |

58 |

2 |

4 |

14 |

0.91 |

25 |

33.7 |

115 |

34.4 |

16 |

85 |

24 |

52 |

5 |

68 |

2 |

4 |

14 |

1.09 |

32 |

42.4 |

140 |

43.1 |

16 |

100 |

26 |

60 |

5 |

78 |

2 |

4 |

18 |

1.58 |

40 |

48.3 |

150 |

49 |

16 |

110 |

26 |

70 |

5 |

88 |

3 |

4 |

18 |

1.76 |

50 |

60.3 |

165 |

61.1 |

18 |

125 |

28 |

85 |

5 |

102 |

3 |

4 |

18 |

2.39 |

65 |

76.1 |

185 |

77.1 |

18 |

145 |

32 |

105 |

5 |

122 |

3 |

4 |

18 |

3.1 |

80 |

88.9 |

200 |

90.3 |

20 |

160 |

34 |

118 |

5 |

138 |

3 |

8 |

18 |

3.77 |

100 |

114.3 |

220 |

115.9 |

20 |

180 |

38 |

140 |

5 |

158 |

3 |

8 |

18 |

4.29 |

125 |

139.7 |

250 |

141.6 |

22 |

210 |

40 |

168 |

5 |

188 |

3 |

8 |

18 |

5.86 |

150 |

168.3 |

285 |

170.5 |

22 |

240 |

44 |

196 |

5 |

212 |

3 |

8 |

22 |

7.22 |

175 |

193.7 |

315 |

196.1 |

24 |

270 |

44 |

224 |

6 |

242 |

3 |

8 |

22 |

9.18 |

200 |

219.4 |

340 |

222 |

24 |

295 |

44 |

247 |

6 |

268 |

3 |

8 |

22 |

9.95 |

250 |

273 |

395 |

276 |

26 |

350 |

46 |

300 |

6 |

320 |

3 |

12 |

22 |

12.69 |

300 |

323.9 |

445 |

327 |

26 |

400 |

46 |

352 |

6 |

370 |

4 |

12 |

22 |

14.4 |

350 |

355.6 |

505 |

359 |

26 |

460 |

53 |

398 |

10 |

430 |

4 |

16 |

22 |

22.36 |

400 |

406.4 |

565 |

410 |

26 |

515 |

57 |

448 |

10 |

482 |

4 |

16 |

26 |

26.85 |

450 |

457 |

615 |

461 |

28 |

565 |

62 |

502 |

10 |

532 |

4 |

20 |

26 |

32.53 |

500 |

508 |

670 |

512 |

28 |

620 |

67 |

552 |

10 |

585 |

4 |

20 |

26 |

37.84 |

600 |

610 |

780 |

614 |

28 |

725 |

75 |

658 |

10 |

685 |

5 |

20 |

30 |

49.32 |

700 |

711 |

895 |

716 |

30 |

840 |

77 |

760 |

10 |

800 |

5 |

24 |

30 |

63.86 |

800 |

813 |

1015 |

818 |

32 |

950 |

84 |

864 |

10 |

905 |

5 |

24 |

33 |

85.19 |

900 |

914 |

1115 |

920 |

34 |

1050 |

88 |

969 |

10 |

1005 |

5 |

28 |

33 |

101.4 |

1000 |

1016 |

1230 |

1022 |

34 |

1160 |

92 |

1071 |

10 |

1110 |

5 |

28 |

36 |

119.7 |

PACKAGING OF SLIP ON FLANGES

Packaging: Slip On Flanges is sleeved into plastic bag individually, ten pieces wrapped with water-proof material, bundled with nylon rope. Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation.

Prevent any damage.

During transportation items are tagged, packed in plastic bags and closed in carton boxes or seaworthy wooden cases.

plywood case,pallet and according to customer's requirment

Marking: Slip On Flanges are marked with alloy name, outside diameter, wall thickness and heat number. Additional information like standard and alloy numbers can be added on request.